TECHNICAL ADVISORY

COUNCIL

FOR

ONSITE WASTEWATER TREATMENT

ADVISORY STATEMENT

SAND FILTER MEDIA

RECIRCULATING SAND FILTERS (RSF’s)

BACKGROUND

Since sand filters were introduced in their present form in Michigan in early 1994, the industry has struggled somewhat with finding the correct sand media. Sand material specifications developed by M.D.O.T. for various purposes were first thought to provide a good guideline for choosing the appropriate materials. But early experience with material processed to existing specifications proved troublesome. The specification for 2 NS sand used in early sand filters has been found to be too broad for that purpose, allowing a gradation with either too many fines, or too high a uniformity coefficient. In either case, the end result may lead to premature plugging of the media in the filter. Further, there exists no M.D.O.T. specification for the recommended grain size distribution found to work best in Recirculating Sand Filters (RSF’s). With no existing standard or specification in Michigan for sand filter media, it is necessary that one be developed.

The Technical Advisory Council published and distributed an Advisory Statement on Intermittent Sand Filter (ISF) Media in July 1998. Following that effort, it was decided to produce a similar document for sand media to be used in Recirculating Sand Filters.

Most sand filter contractors and designers have simply searched to find what was readily available. The TAC feels that we need to publicize and distribute what we feel to be the ideal media with the hope that suppliers will start processing this material for use.

MEDIA RECOMMENDATION

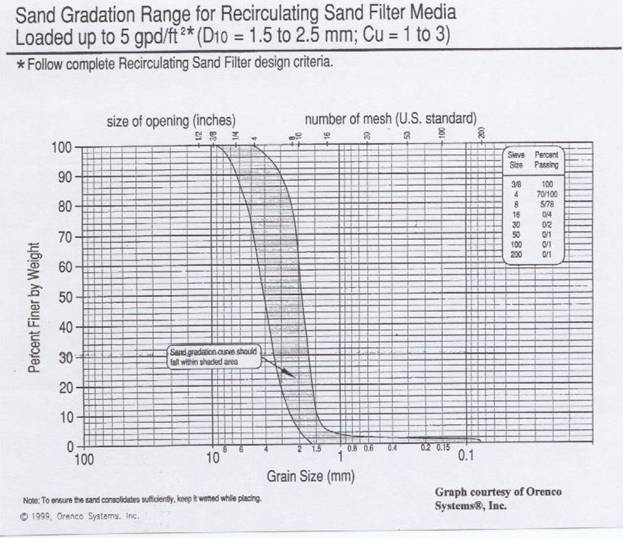

With the above stated goals in mind, the TAC is recommending that the attached specification be used for sand filter media in all RECIRCULATING SAND FILTERS (also known as MULTIPLE-PASS SAND FILTERS). This media specification was previously published as a recommendation by Orenco Systems, Inc. for recirculating sand filters.

The TAC recognizes that in some parts of the state it may be difficult to get this specific media. It is their hope that with the publication and adoption of this recommendation, suppliers will step forward to process this material. However, the raw materials are not always available.

For this reason, we are including in this recommendation the following discussion on the factors to consider when selecting a media gradations for an RSF.

DIFFERENCES BETWEEN RSF’s AND ISF’s

The media in an RSF will be typically dosed with 3 to 5 times as much effluent than an ISF. This means that the effluent will need to pass down through the media faster than in an ISF, requiring a larger grain size. The larger grain sizes will also allow air to circulate easier through the media --- if the pore spaces are not flooded. RSF’s require careful thought to distribution methods and dose frequencies, as well as means of allowing the media a free source of air. RSF’s should not be covered with a soil cover. In fact, the TAC recommends that the cover consist only of stone or a light layer of wood chips. A maintenance effort must be made to keep any organic materials that may be placed or fall on top of the filter from decaying and washing down into the filter media.

Flow modulation through the use of programmable timers is essential. Peak loading periods are intensified in RSF’s due to the recirculation ratio. So it is very important that timed dosing be used to spread these flows out over longer periods of time. This, of course, does require that storage be designed into the system.

FACTORS TO CONSIDER

Like ISF’s, it is extremely important that the media be clean and free of excessive fines

(<1.00 mm). If the sand filter media has too many fines, there is a danger of plugging the media with solids that build up due to slow permeability. If a media is chosen that is “too coarse”, the wastewater will pass through too rapidly and treatment will not be as good. It is therefore very important to obtain the correct media. If the ideal media cannot be found, the designer may be able to lower the loading rate to compensate.

However, other design choices that are made may have as significant an impact on the filter performance as the choice of media. The designer must become familiar with the relationship between media size, loading rates, method of effluent distribution, timed dosing, dose volumes, and other factors --- and how each impacts the other --- such that the proper design choices can be made, if needed, to compensate for construction constraints in a particular case.

Research and experience has shown that best treatment and best performance is achieved by slow, unsaturated “FILM FLOW” of the wastewater downward over the surface of the media particles. This is accomplished with what has come to be known as “MICRO-DOSING.” This means small, well-distributed doses of effluent applied to the media in frequent, short periods, such that the surface of the media is wetted, but pore spaces surrounding the media particles are not filled with effluent. Programmable timer settings, lateral design, hole size and spacing, etc., as well as media size, are all inter-related in the effort to accomplish this. (For further information on effluent application rates, dosing size and frequency, the reader is referred to Small and Decentralized Wastewater Management Systems, by Ron Crites and George Tchobanoglous, McGraw-Hill, 1998.

It should also be noted that, because RSF’s use a little larger media, film flow is harder to accomplish, but essential. Filling the pore spaces of the media with larger doses of effluent will not only reduce treatment efficiency, but the downward flow will tend to scour the biomass from the media surface, and flush it to the bottom of the filter where it may be washed out into the soil absorption system, or back into the recirculation tank.

CLEAN STONE

Dirty stone on the top of a sand filter can lead to filter failure through plugging of the stone/sand interface. Dirty stone around the sand filter underdrain and within the drainfield can lead to clogging of the stone/soil interface in the drainfield. IT IS IMPERATIVE THAT CLEAN WASHED STONE BE USED IN THE CONSTRUCTION OF EVERY SAND FILTER. ACCEPT NO SUBSTITUTES. Many times stone is delivered to the site clean, but it can be contaminated in handling at the site. Contractors should be advised of this danger, and educated on how to handle stone so that it does not become contaminated during construction. In fact, this same practice should be followed in all drainfield construction.

------------------------------------------------------------------------------------------------------------------

NOTE: The media recommendation contained herein is for RECIRCULATING (MULTIPLE-PASS) SAND FILTERS ONLY. See the TAC Advisory Statement on Intermittent Sand Filter (ISF) Media, issued in July 1998, for the media size that should be used for intermittent sand filters.

------------------------------------------------------------------------------------------------------------------

This recommendation adopted by the Technical Advisory Council for Onsite Wastewater Treatment at their meeting on August 29, 2001.

========================================================================================